rockwell hardness test errors|rockwell hardness tester diagram : agent This guide explains the causes of variability in Rockwell hardness test results and provides good practice recommendations for reducing measurement errors. It also covers the test .

Programa The Chef - Band Entretenimento. ENTRAR. The Chef. Página inicial. Ao vivo. Vídeos. Dicas. Siga o The Chef nas redes. Band Receitas.

{plog:ftitle_list}

WEB24 de out. de 2023 · La Catrina goes global. In 1947, Diego Rivera further immortalized La Catrina when he made her the focal point of one of his most famous murals, “Dream of .

Learn about the Rockwell hardness test, a differential-depth method that measures the residual indentation depth of a material. Find out the advantages, disadvantages, and applications of different Rockwell methods .

Learn how to reduce measurement errors in Rockwell hardness tests of metallic materials with this NIST recommended practice guide. The guide explains the causes of .

Certaincommercial. entities, equipment, ormaterials. may. be. identifiedin. this. document. in. order. todescribe. anexperimentalprocedure. or. concept. adequately .

A movement of just 0.001” could result in an error of over 10 Rockwell points. Factors like material type and thickness will require different scales. There are over 30 different Rockwell scales with their own . Learn how to choose the right scale, indenter, and anvil for accurate and reliable Rockwell hardness testing. Avoid common errors and pitfalls that can affect the test results and material performance.This guide explains the causes of variability in Rockwell hardness test results and provides good practice recommendations for reducing measurement errors. It also covers the test .Learn about the Rockwell hardness test, a common and fast method to measure the depth of penetration of an indenter into a material. Find out the advantages, limitations, and .

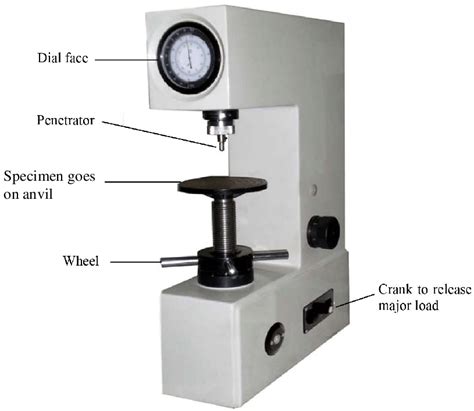

The Rockwell test consists of measuring the additional depth to which a carbide ball or Brale® diamond penetrator is forced by a heavy (major) load beyond the depth of a previously applied .A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the .

Rockwell testing falls into two categories: Regular Rockwell testing (e.g., C and B scales) and Rockwell superficial testing (e.g., 30 N and 30 T scales). High Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness Testing In order to reduce the testing errors in Rockwell hardness of metal specimens and improve the accuracy of hardness testing, several methods had been tried out and examined based on GB/T 230 and .The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a Rockwell test. The Rockwell test is generally easier to perform, and more accurate than other types of hardness testing methods .

Rockwell Hardness Testing Machine: Comes in different scales (A, B, C, etc.) to match various hardness levels and types of materials. Indenter: Usually, a diamond cone or hardened steel ball is selected according to the material under examination. Test specimen: the material or component undergoing evaluation. Methodology: Steps: 1.1.9 At the user level, hardness reference blocks are used to calibrate the industrial hardness testing machines in an indirect way, after they have been directly calibrated. 1.10 The stability of hardness scales is essentially underpinned by this two-step calibration procedure for .These methods of hardness testing are valuable tools in determining “shallow layer hardness,” such as surface hardness, coating hardness, and case depth. Additionally, selective testing of particular grains or constituents could not be performed without these tests. in necessary. The choice is not only between the regular hardness test and superficial hardness test, with three different major loads for each, but also between the diamond indenter and the 1/16, 1/8, 1/4 and 1/2 in. diameter steel ball indenters.

bilingual seal of literacy test

1. NAMES AND FUNCTIONS OF COMPONENTS . Front panel (See p.3) Test force sequence switch: AUTO: Performs one cycle of hardness measurement DURATION: Used for appling and removing test force There are myriads of hardness tests out there, however the Rockwell hardness test is the most common hardness test used in the metalworking industry today, due to its speed and accuracy. The test must be carried out with a specific type of scale or tester, called a Rockwell hardness scale. How It Works

A standardized test procedure used to determine the hardenability of steel, the Jominy test (End Quench Test) can be performed using either the Vickers or Rockwell hardness test method. When selecting which to use, you should consider relevant standards, as well as the usual criteria when choosing between different types of hardness test.

The RockGen Rockwell Hardness Testing System was designed to test the hardness level of metal based on the indentation they leave on a tested material according to the Rockwell scale. The machine is capable of measuring the resolution of a material to a 0.001″.

bilingual seal test in washinton

SCOPE. The Rockwell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical characteristics of metallic materials, and may be useful in quality control and selection of materials. In the Rockwell hardness test, the measure of the hardness is not an indentation surface but an indentation depth. Either a carbide ball or a rounded diamond cone with a tip angle of 120° and a tip radius of 0.2 mm serves as the indenter. The indentation depth can be read directly from a dial gauge via the traverse path of the testing machine.While the Rockwell hardness test has its uniqueness, its accuracy is also guided by some critical factors you need to consider before engaging in this test method. . resulting in errors. Material Type – When no hardness scale is specified for a material type, it is often critical to identify the material type so that you can verify the .Description of Rockwell Test; ASTM A 370 says: “In this test a hardness value is obtained by determining the depth of penetration of a diamond point or a steel ball into the specimen under certain arbitrarily fixed conditions. A minor load is first applied which causes an initial penetration, sets the penetrator on the material and holds it

The Rockwell hardness test continues to be applied as a tool for assessing the properties of a product while the tolerances on the acceptable material hardness have become tighter and tighter. Adhering to “good practice” . calibrations is a beneficial step to reducing measurement errors. The purposeSee also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload .1. Define Hardness. 2. Applications of Rockwell Hardness A ± Scale, B-Scale, C-Scale. 3. Type of Indentor used in the Three Different Scales of Rockwell Hardness Test. 4. Different Types of Hardness Testing Methods. 5. Size of the Ball to be used in Ball Indentor of Rockwell Hardness Test. 6. Di ameters of the different Balls used in Brinell .3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually apply the specified load using the machine.The load should be maintained for a predetermined dwell time, usually between 10 to 15 seconds.

rockwell hardness tester procedure pdf

International Standards Organization – Rockwell Hardness Test Part 1 – Test Method (ISO 6508-1 Metallic Materials) The reason all steel product manufacturers use the Rockwell hardness scale is that it allows uniformity in reporting test results. Everyone in the steel industry recognizes the Rockwell hardness scale. Certaincommercial. entities, equipment, ormaterials. may. be. identifiedin. this. document. in. order. todescribe. anexperimentalprocedure. or. concept. adequately .

This set of Testing of Materials Multiple Choice Questions & Answers (MCQs) focuses on “Rockwell Hardness Test”. 1. Which hardness test is most widely used in the US? a) Brinell b) Vickers c) Shore d) Rockwell View Answer Rockwell Hardness Testing Theory. Rockwell hardness testing has several indenter types which in turn require separate major loads (kg). Figure 1 reflects common Rockwell scales used and their corresponding major loads. Figure 1. When Rockwell hardness testing, a minor load of 10kg is applied to the indenter used on the material being tested.What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared to other methods, like Vickers or Brinell hardness testing. Another advantage is the small area of indentation needed to carry out the .Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .

A widely used variant of the Rockwell hardness test is the superficial Rockwell test, wherein the minor load is 3 N and the major loads are 15, 30, or 45 N.Further details on the Rockwell superficial hardness scales are available in the relevant ASTM standards (ASTM 1984).The Rockwell hardness values are expressed as a combination of hardness number and a scale .

rockwell hardness tester procedure

biliteracy seal practice test

webAhora te explicaremos cómo descargar el software de Bodog en tu computadora: Paso 1. Dirígete a la página de Bodog. Asegúrate de entrar en la página oficial, te dejamos el .

rockwell hardness test errors|rockwell hardness tester diagram